USTEK is a many-faceted source of metal components for customers in a broad range of industries. With decades of experience in the metal component industry, we have established close relationships with a dependable network of quality suppliers. It is our goal to help you find the highest quality components as quickly as possible, within your budget.

When you partner with USTEK, all you have to do is place the call, and we will begin sourcing the exact metal components you need, from housings and brackets to tubing and terminals. No matter what your requirements, we have the knowledge, experience, and connections to make sure that you get the parts you need when you need them.

Contact Us

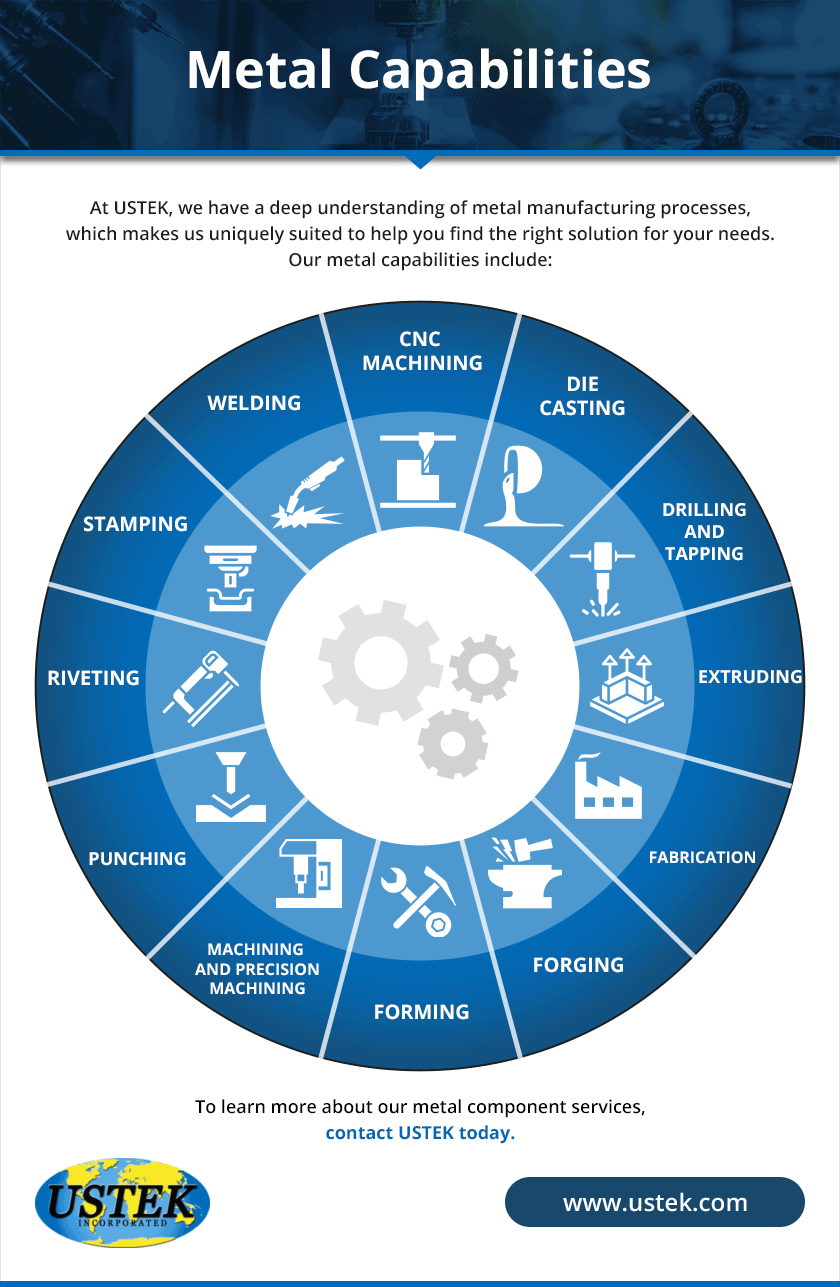

Metal Capabilities

(Click to Expand)

At USTEK, we have a deep understanding of metal manufacturing processes, which makes us uniquely suited to help you find the right solution for your needs. We know that each fabrication method has its unique benefits and costs, and we work closely with you to determine which method is ideal for your application. Our metal capabilities include:

At USTEK, we have a deep understanding of metal manufacturing processes, which makes us uniquely suited to help you find the right solution for your needs. We know that each fabrication method has its unique benefits and costs, and we work closely with you to determine which method is ideal for your application. Our metal capabilities include:

CNC Machining

Computer numerical control (CNC) machining uses specialized software to accurately control the machinery and its tooling to remove material from a metal stock to create the desired part or component.

Die Casting

Die casting is a metal fabrication process that uses pre-shaped molds or dies. Molten metal is injected into the die and allowed to cool and harden into the desired shape. Die casting molds can be reused to produce multiple identical components, making this process ideal for mass production.

Drilling and Tapping

Drilling and tapping are used to create holes of specific diameters and depths using a specialized drill head or tap. Standard drilling creates a smooth hole, while tapping creates a threaded hole. We are tooled for both American standard and international metric threads.

Extruding

Extrusion involves forcing metal through or around a die to create the desired shape. The piece is cut to a specified length, creating a component with a consistent diameter or internal cavity along its full length.

Fabrication

Fabrication is a categorical term that refers to all methods of cutting, milling, shaping, bending, stamping, forging, or molding metals to create a part or finished product. Fabrication methods can create products from raw materials and partially completed workpieces.

Forging

Forging uses compressive force and impact with a hammer or die to create the desired component shape. Depending on the material being forged, this process can be performed at ambient or elevated temperature.

Forming

Forming refers to reshaping metal without melting the material. This allows molded products to maintain their structural integrity and strength. Since forming is conducted without melting the metal, material handling is less complex than other methods.

Machining and Precision Machining

Machining refers to subtractive metal manufacturing that removes material from a base stock or sheet to create a finished product. Precision machining is often completed using CNC technology. Machining processes include cutting, milling, sawing, and drilling.

Punching

Punching uses a high-pressure press and a die to create holes in a sheet or blank. Depending on the design, the punched part could be removed and subsequently tapped or CNC finished.

Riveting

Riveting is a type of forging that creates a joint between two component pieces. The pieces are held together by a long, smooth piece of metal called a rivet.

Stamping

Stamping is similar to punching, but rather than creating holes, this process indents the sheet or blank in the shape of the die. Stamping uses compressive force to stamp shapes, images, letters, and numbers onto metal components.

Welding

Welding is a metal manufacturing process that joins two pieces together using heat and pressure. It is a highly versatile method that can be used on pieces of any size and shape, which makes it one of the most popular methods for joining metal parts.

Types of Materials

At USTEK we understand that the right material is critical, which is why we maintain a broad selection of materials for you to choose from. Our comprehensive material offerings include:

- Aluminum

- Beryllium

- Brass

- Bronze

- Cadmium

- Carbon Steel

- Copper

- Gold

- Magnesium

- Stainless Steel

- Silver

- Titanium

- Tungsten

- Zinc

Metal Finishes

Finishing is a critical aspect of the manufacturing process. USTEK offers a variety of finishing services to ensure that your product is finished and ready to assemble. These include:

- Anodizing

- Black oxide

- Electro-Polishing

- Painting

- Plating

- Polishing

- Powder Coating

Metal 3D Prototypes

Prior to committing to a final design with its investment in tooling, designers have an option: 3D printing. Using the customer-supplied 3D CAD files we could provide our customers with polymer models and even functional metal parts at a small fraction of the cost of conventional metal fabrication methods.

Options Abound – Just Ask USTEK

Product managers and procurement staff have come to rely on USTEK’s wide-ranging background in material selection. We could offer suggestions of alternative alloys, finishing techniques, and even the substitution of engineering polymers for metals.

Outstanding Metal Components by USTEK

At USTEK, we are committed to ensuring that our customers have the exact metal components they need for their application. No matter what your needs, we have the knowledge, experience, and partnerships to help you receive metal parts at competitive prices with a quick turnaround.

To learn more about our metal component services, contact USTEK today.