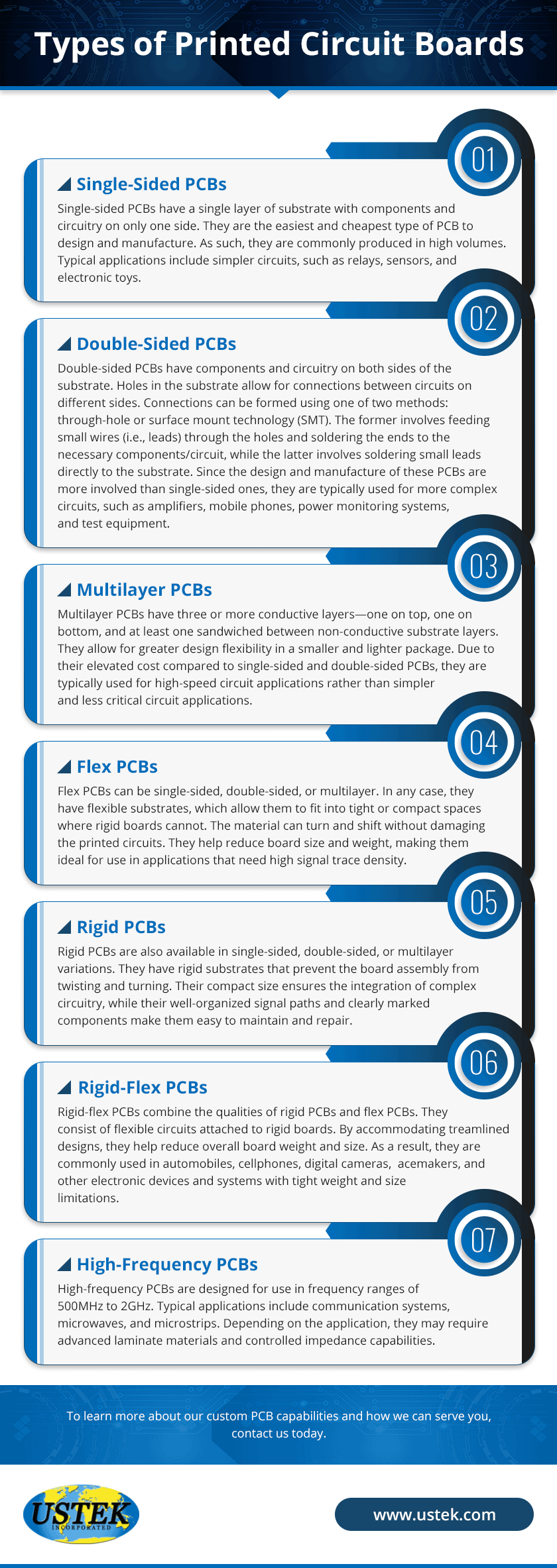

Are you designing a new electronic device or upgrading an existing one? If so, chances are you’ll need printed circuit boards (PCBs). The self-contained boards mechanically support and electrically connect electrical and electronic components. The components are located on the surface of a non-conducting board (i.e., the substrate) and soldered to printed circuits (i.e., small layers of conductive material deposited on one or more sides of the substrate). When designed and manufactured properly, PCBs help ensure the device assembly in which they are installed operates and performs as intended.

PCBs come in many variations, each of which is suitable for different electronic applications. Below, we highlight and discuss the various types that are available.

Single-Sided PCBs

Single-sided PCBs have a single layer of substrate with components and circuitry on only one side. They are the easiest and cheapest type of PCB to design and manufacture. As such, they are commonly produced in high volumes. Typical applications include simpler circuits, such as relays, sensors, and electronic toys.

Double-Sided PCBs

Double-sided PCBs have components and circuitry on both sides of the substrate. Holes in the substrate allow for connections between circuits on different sides. Connections can be formed using one of two methods: through-hole or surface mount technology (SMT). The former involves feeding small wires (i.e., leads) through the holes and soldering the ends to the necessary components/circuit, while the latter involves soldering small leads directly to the substrate. Since the design and manufacture of these PCBs are more involved than single-sided ones, they are typically used for more complex circuits, such as amplifiers, mobile phones, power monitoring systems, and test equipment.

Multilayer PCBs

Multilayer PCBs have three or more conductive layers—one on top, one on bottom, and at least one sandwiched between non-conductive substrate layers. They allow for greater design flexibility in a smaller and lighter package. Due to their elevated cost compared to single-sided and double-sided PCBs, they are typically used for high-speed circuit applications rather than simpler and less critical circuit applications.

Flex PCBs

Flex PCBs can be single-sided, double-sided, or multilayer. In any case, they have flexible substrates, which allow them to fit into tight or compact spaces where rigid boards cannot. The material can turn and shift without damaging the printed circuits. They help reduce board size and weight, making them ideal for use in applications that need high signal trace density.

Rigid PCBs

Rigid PCBs are also available in single-sided, double-sided, or multilayer variations. They have rigid substrates that prevent the board assembly from twisting and turning. Their compact size ensures the integration of complex circuitry, while their well-organized signal paths and clearly marked components make them easy to maintain and repair.

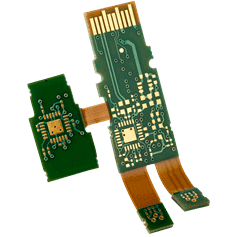

Rigid-Flex PCBs

Rigid-Flex PCBs

Rigid-flex PCBs combine the qualities of rigid PCBs and flex PCBs. They consist of flexible circuits attached to rigid boards. By accommodating streamlined designs, they help reduce overall board weight and size. As a result, they are commonly used in automobiles, cellphones, digital cameras, pacemakers, and other electronic devices and systems with tight weight and size limitations.

High-Frequency PCBs

High-frequency PCBs are designed for use in frequency ranges of 500MHz to 2GHz. Typical applications include communication systems, microwaves, and microstrips. Depending on the application, they may require advanced laminate materials and controlled impedance capabilities.

Contact USTEK for Your PCB Needs Today!

For PCBs you can trust, turn to the experts at USTEK! As a premier custom manufacturer of electrical and metal components with experience designing and constructing PCBs for various industries, we can work with you to develop a custom PCB solution that fully meets your needs. Whether you require basic, single-sided PCBs for simple circuits or complex, multilayer PCBs with high-frequency capabilities, we’ve got you covered. To learn more about our custom PCB capabilities and how we can serve you, contact us today.