3D printing is the process of creating three-dimensional solid objects using computer-created designs. Also referred to as additive manufacturing, 3D printing builds up layers of material one on top of the other until it creates a 3D part. 3D printing differs from the more common subtractive manufacturing methods in which material is removed from a larger block of material to form the final product. As such, 3D printing results in less wastage and more cost-effective products.

3D printing technologies consist of three broad types: sintering, stereolithography, and melting. Sintering heats the material below its melting point to create high-resolution products. Stereolithography uses photopolymerization to create 3D parts. Melting uses lasers, electron beams, or electric arcs to melt materials together and print objects. 3D printing is an ideal manufacturing method to rapidly produce prototypes with complex geometries and it is compatible with a variety of different materials.

3D Printing Metal Parts

3D printing is most often associated with plastic materials, however, you can 3D print products from metal. We use metal 3D printing for rapid prototyping and production of components for industries such as aerospace and mechanical engineering. One of the most common 3D printing methods for metal is sintering in which layers of powdered metal are melted together or combined with another material for nozzle delivery.

Many types of metals are used for 3D printing, including titanium, aluminum, stainless steel, and copper, while others are not ideal. Compatible metals have various properties that make them suitable for 3D printing. For example, stainless steel has significant corrosion resistance. This makes it ideal for printing steam turbines, pipes, and valve parts.

Some metals with properties such as burning in high temperatures instead of melting are not safe for 3D printing. Metals with very high melting points are also not ideal for 3D printing.

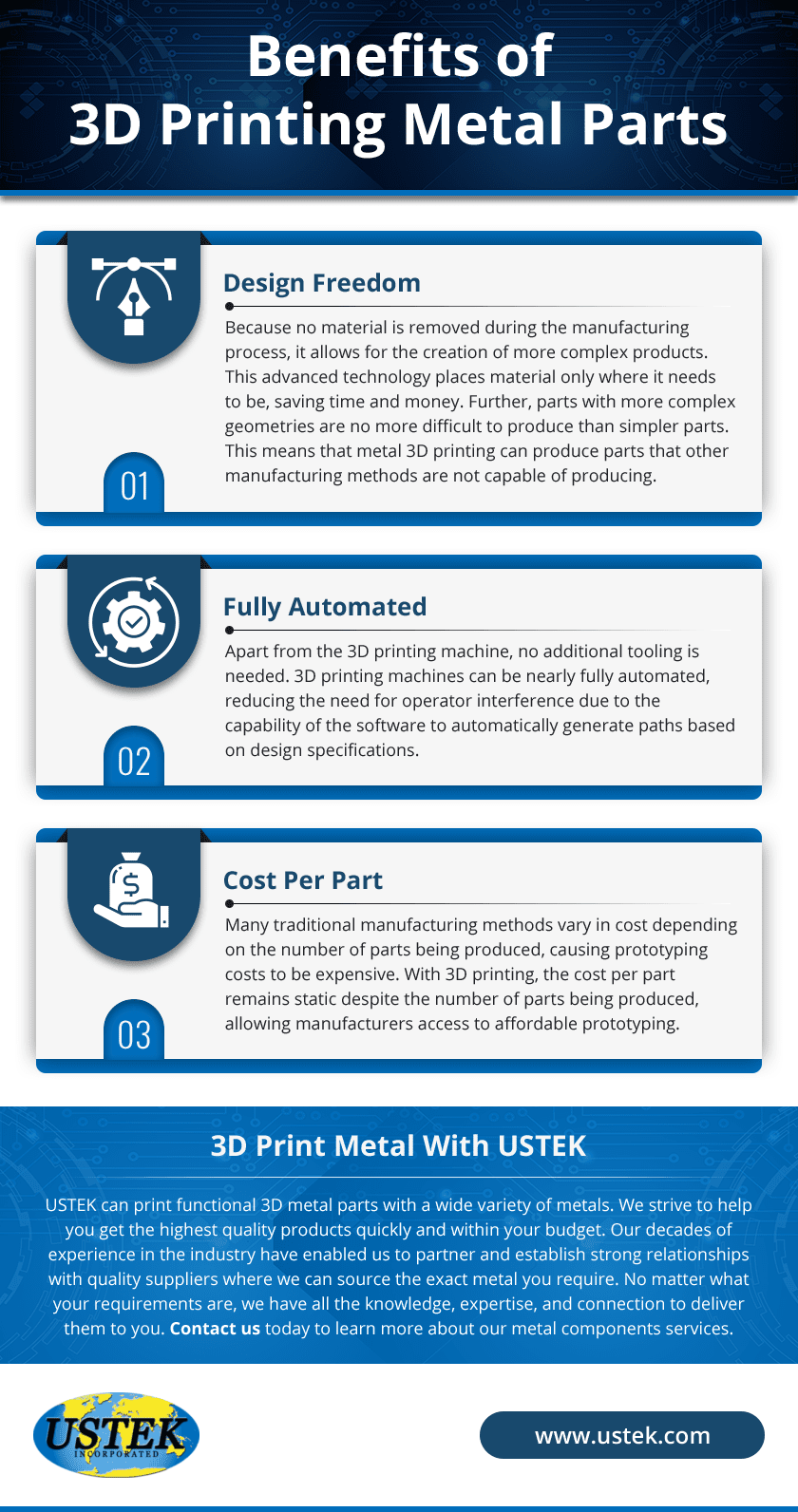

Benefits of 3D Printing Metal Parts

As an additive process, 3D printing differs greatly from traditional manufacturing methods. This unique production method offers a range of benefits, including:

- Design freedom: Because no material is removed during the manufacturing process, it allows for the creation of more complex products. This advanced technology places material only where it needs to be, saving time and money. Further, parts with more complex geometries are no more difficult to produce than simpler parts. This means that metal 3D printing can produce parts that other manufacturing methods are not capable of producing.

- Fully automated: Apart from the 3D printing machine, no additional tooling is needed. 3D printing machines can be nearly fully automated, reducing the need for operator interference due to the capability of the software to automatically generate paths based on design specifications.

- Cost per part: Many traditional manufacturing methods vary in cost depending on the number of parts being produced, causing prototyping costs to be expensive. With 3D printing, the cost per part remains static despite the number of parts being produced, allowing manufacturers access to affordable prototyping.

3D Printed Metal Parts From USTEK

USTEK is a source of metal products for clients in all ranges of industries. We have hands-on experience in metal manufacturing processes that enable us to offer personalized solutions for all your needs. Our capabilities in metal include CNC machining, die casting, drilling and tapping, extruding, forging, fabrication, machining, precision machining, forming, punching, riveting, stamping, and welding.

Using your supplied 3D CAD files, we can provide you with polymer models or functional metal parts at a very low cost. We understand that the right choice of metal is crucial, which is why we have a wide variety of metal types you can select from. They include:

- Aluminum

- Brass

- Bronze

- Cadmium

- Copper

- Gold

- Magnesium

- Silver

- Carbon

- Steel

- Beryllium

- Stainless

- Steel

- Zinc

- Tungsten

- Titanium

3D Print Metal With USTEK

USTEK can print functional 3D metal parts with a wide variety of metals. We strive to help you get the highest quality products quickly and within your budget. Our decades of experience in the industry have enabled us to partner and establish strong relationships with quality suppliers where we can source the exact metal you require. No matter what your requirements are, we have all the knowledge, expertise, and connection to deliver them to you. Contact us today to learn more about our metal components services.