Some electrical projects have highly specific requirements and restrictions that necessitate the use of complex circuitry. While a standard circuit board with industry norm specifications may be applicable for these situations, a specialty or custom printed circuit board (PCB) solution is often more appropriate.

Contact Us

Benefits of Using Tailored Printed Circuit Boards

PCBs can be designed and manufactured for a wide range of industrial and commercial applications, from heavy equipment for production operations to cellphones for consumer use. By tailoring them to the exact needs of the application, manufacturers can trust that the components will operate and perform as intended in the assembled device or system. Other benefits of using a custom PCB over a standard circuit board include:

- Smaller footprint, greater circuit density. Custom PCBs can be optimized to suit the performance requirements and space restrictions of the application, meaning the circuitry could be condensed to achieve better transmission as well as minimize the size of the component. This could include something as simple as adding additional board layers or decreasing the trace/space dimensions.

- Lower labor costs, higher labor savings. Custom PCB production can be automated to decrease labor costs while increasing accuracy, precision, or quality. Additionally, the design of the PCB can be engineered to minimize installation, replacement, and servicing requirements.

- No need for instructional and testing labels. Custom PCBs can have legends directly printed onto them, which eliminates the need for separate printed decals.

While custom PCBs are highly beneficial for certain electrical applications, they are not suitable for every project. They are best suited for those involving high production volumes that do not use frequently changing designs since the initial design and tooling costs can be expensive.

Cost Considerations for Specialty Printed Circuit Boards

Is a more sophisticated PCB right for your project? The answer to this question depends on your project’s complexity and budget. Your PCB manufacturing partner can help you perform cost-benefit analyses so you can determine whether your project merits investment in a custom solution. Some of the factors that they may go over that affect the cost of a custom PCB include:

- Custom PCB Design: An experienced team is required to develop a design that meets all the application’s requirements for functionality and space. Additionally, the layout of the PCB needs to be designed with manufacturability in mind to avoid problems during the fabrication, assembly, and field installation stages. The engineering costs for this will vary depending on your specifications for the circuit board.

- Innovative PCB Testing: Testing is an important aspect of custom circuit board production. If you don’t already have your own test procedures in place, custom functional test fixtures and procedures might need to be developed for your project. Depending on your project and industry, the circuit board might have to meet certain requirements (e.g., IPC 6011).

- First article PCB Prototyping: It is important to create prototypes before proceeding to final production. These units allow you and your manufacturing partner to discover and resolve any unanticipated design issues. Some customers already have their prototype design completed and just need a manufacturer to produce it, while others still need to prepare the initial prototype design. In either case, the cost of prototyping can only be quoted once the final bill of materials has been developed.

- Cost-engineered PCB Manufacturing: During the manufacturing stage, the engineering team will work closely with you before production starts. They will conduct design for manufacturing (DFM) and new product release meetings to ensure your team approves all aspects.

Specialty Circuit Boards From USTEK

Need a specialty circuit board for your electrical project? Turn to the experts at USTEK! As a premier manufacturer of specialty electrical and metal components, with extensive experience designing and constructing PCBs, we have the knowledge and skills to develop and deliver a solution that meets your exact needs.

- Running a high-temperature profile for RoHS? We can support you with the usual high Tg (high glass transition) material at Tg180°C or offer a lower-cost alternative with a close equivalent at Tg170°C.

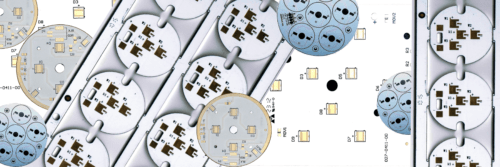

- Want to combine two, three, eight, or more rigid PCBs together without a harness? We can provide a panel of dissimilar boards that allows you to stuff and solder multiple boards in a single pass, resulting in reduced cutting SMT reflow time and final assembly time. We could assist in your designing hybris rigid-flex arrays that interlink several boards without sockets, connectors, or harnesses.

- Seeking a way to differentiate product use, model, design level, or target market of your circuit boards? We offer a broad selection of solder mask colors that will allow immediate identification at no surcharge.

Some of the USTEK offerings include:

| Tg Range | Flexibility | Material Types |

|---|---|---|

| FR-4 Tg130 | CEM-1 | Ceramic |

| FR-4 Tg150 | CEM-3 | Aluminum Core Mod. w/mk |

| FR-4 Tg170 | Rigid-Flex | Aluminum Core High w/mk |

| FR-4 Tg180 | BendFlex | |

| FR-406 | Flex Polyimide | |

| FR-5 | Flex Polyester | |

| 370HR |

To learn more about our custom PCB capabilities or discuss your specifications with one of our team members, contact us today.