When partnering with USTEK Incorporated, customers in a wide array of industries have access to an extensive collection of metal fabrication services, a network of quality suppliers, and an expert team backed by decades of experience.

While high-quality performance in metal components is paramount, we also understand the importance of metal fabrication materials in producing that quality workmanship. For that reason, USTEK offers numerous types of metals to best suit your unique application. Learn more about the various metals and services we supply and partner with a team that can work with you to determine the best material and metalworking technique for your project.

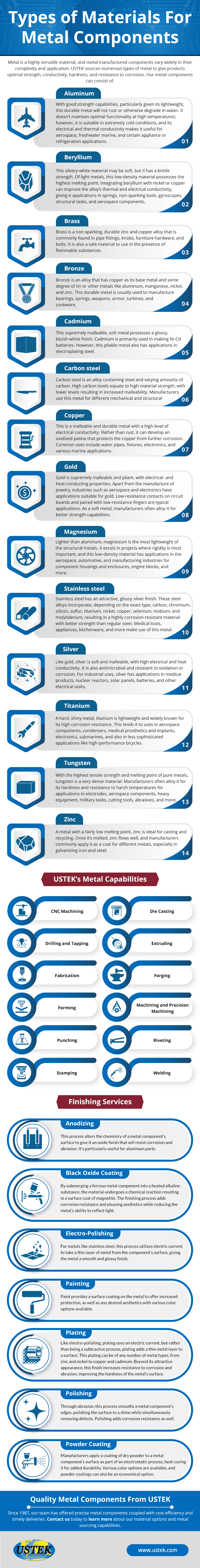

Types of Materials for Metal Components

Metal is a highly versatile material, and metal manufactured components vary widely in their complexity and application. USTEK sources numerous types of metal to give products optimal strength, conductivity, hardness, and resistance to corrosion. Our metal components can consist of:

- Aluminum. With good strength capabilities, particularly given its lightweight, this durable metal will not rust or otherwise degrade in water. It doesn’t maintain optimal functionality at high temperatures; however, it is suitable in extremely cold conditions, and its electrical and thermal conductivity makes it useful for aerospace, freshwater marine, and certain appliance or refrigeration applications.

- Beryllium. This silvery-white material may be soft, but it has a brittle strength. Of light metals, this low-density material possesses the highest melting point. Integrating beryllium with nickel or copper can improve the alloy’s thermal and electrical conductivity, giving it applications in springs, non-sparking tools, gyroscopes, structural tasks, and aerospace components.

- Brass. Brass is a non-sparking, durable zinc and copper alloy that is commonly found in pipe fittings, knobs, furniture hardware, and bolts. It is also a safe material to use in the presence of flammable substances.

- Bronze. Bronze is an alloy that has copper as its base metal and some degree of tin or other metals like aluminum, manganese, nickel, and zinc. This durable metal is usually used to manufacture bearings, springs, weapons, armor, turbines, and cookware.

- Cadmium. This supremely malleable, soft metal possesses a glossy, bluish-white finish. Cadmium is primarily used in making Ni-Cd batteries. However, this pliable metal also has applications in electroplating steel.

- Carbon steel. Carbon steel is an alloy containing steel and varying amounts of carbon. High carbon levels equate to high material strength, with lower levels resulting in increased malleability. Manufacturers use this metal for different mechanical and structural components as well as tools.

- Copper. This is a malleable and durable metal with a high level of electrical conductivity. Rather than rust, it can develop an oxidized patina that protects the copper from further corrosion. Common uses include water pipes, fixtures, electronics, and various marine applications.

- Gold. Gold is supremely malleable and pliant, with electrical- and heat-conducting properties. Apart from the manufacture of jewelry, industries such as aerospace and electronics have applications suitable for gold. Low-resistance contacts on circuit boards and paired with low-resistance fingers are typical applications. As a soft metal, manufacturers often alloy it for better strength capabilities.

- Magnesium. Lighter than aluminum, magnesium is the most lightweight of the structural metals. It excels in projects where rigidity is most important, and this low-density material has applications in the aerospace, automotive, and manufacturing industries for component housings and enclosures, engine blocks, and more.

- Stainless steel. Stainless steel has an attractive, glossy silver finish. These steel alloys incorporate, depending on the exact type, carbon, chromium, silicon, sulfur, titanium, nickel, copper, selenium, niobium, and molybdenum, resulting in a highly corrosion-resistant material with better strength than regular steel. Medical tools, appliances, kitchenware, and more make use of this metal.

- Silver. Like gold, silver is soft and malleable, with high electrical and heat conductivity. It is also antimicrobial and resistant to oxidation or corrosion. For industrial uses, silver has applications in medical products, nuclear reactors, solar panels, batteries, and other electrical tasks.

- Titanium. A hard, shiny metal, titanium is lightweight and widely known for its high corrosion resistance. This lends it to uses in aerospace components, condensers, medical prosthetics and implants, electronics, submarines, and also in less sophisticated applications like high-performance bicycles.

- Tungsten. With the highest tensile strength and melting point of pure metals, tungsten is a very dense material. Manufacturers often alloy it for its hardness and resistance to harsh temperatures for applications in electrodes, aerospace components, heavy equipment, military tasks, cutting tools, abrasives, and more.

- Zinc. A metal with a fairly low melting point, zinc is ideal for casting and recycling. Once it’s melted, zinc flows well, and manufacturers commonly apply it as a coat for different metals, especially in galvanizing iron and steel.

Metal Component Applications

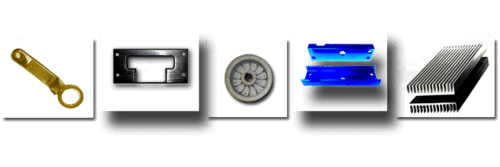

With this range of high-quality material choices, USTEK supplies metal components for various industries and applications. Our metal components are ideal for:

Appliances and Electronics

Appliance and home electronics manufacturers use various durable metal components to lend advantages such as heat stability to their products. This includes precision parts like smoke detector battery terminals, garage door opener brackets, c-clips, and fire extinguisher valve caps.

Automotive and Transportation

These industrial sectors rely on precision components that can be reliably and consistently reproduced. Metal components made of strong and lightweight metals are useful in manufacturing fittings, wheel hubs, taillight and engine caps, baffle cones, and rocket motor nozzles. These applications cut across different means of transportation, including air, water, vehicle, and rail transport.

Energy Applications

Various types of metals are applicable in power generation components, such as copper tubing, enclosures for batteries or power supplies, and more.

Structural Subassemblies

Metals can generate units assembled separately but designed to be used in larger manufactured products. Some subassemblies that use metal components include connector plates, frames, access panels, brackets, and mounting plates.

Telecommunications

The telecommunications industry uses metal-fabricated parts for a wide range of applications, including antennas, frames, chassis enclosures, and heat sinks. Metal provides the durability, tight tolerances, and weather resistance that this sector needs in its components.

USTEK’s Metal Capabilities

At USTEK, our experience in metal components and our extensive knowledge base in various types of metals position us as a solution for your metal fabrication needs. To provide comprehensive service to our customers, we provide access to the following services:

- CNC machining

- Die casting

- Drilling and tapping

- Extruding

- Fabrication

- Forging

- Forming

- Machining and precision machining

- Punching

- Riveting

- Stamping

- Welding

However, USTEK has far more to offer than initial component fabrication.

Finishing Services

At USTEK, we offer various finishing services to guarantee that your product is in its best form for assembly. Some of our finishing options include:

- Anodizing. This process alters the chemistry of a metal component’s surface to give it an oxide finish that will resist corrosion and abrasion. It’s particularly useful for aluminum parts.

- Black oxide coating. By submerging a ferrous metal component into a heated alkaline substance, the material undergoes a chemical reaction resulting in a surface coat of magnetite. The finishing process adds corrosion resistance and pleasing aesthetics while reducing the metal’s ability to reflect light.

- Electro-polishing. For metals like stainless steel, this process utilizes electric current to take a thin layer of metal from the component’s surface, giving the metal a smooth and glossy finish.

- Painting. Paint provides a surface coating on the metal to offer increased protection, as well as any desired aesthetics with various color options available.

- Plating. Like electro-polishing, plating uses an electric current, but rather than being a subtractive process, plating adds a thin metal layer to a surface. This plating can be of any number of metal types, from zinc and nickel to copper and cadmium. Beyond its attractive appearance, this finish increases resistance to corrosion and abrasion, improving the hardness of the metal’s surface.

- Polishing. Through abrasion, this process smooths a metal component’s edges, polishing the surface to a shine while simultaneously removing defects. Polishing adds corrosion resistance as well.

- Powder coating. Manufacturers apply a coating of dry powder to a metal component’s surface as part of an electrostatic process, heat-curing it for added durability. Various color options are available, and powder coatings can also be an economical option.

Metal 3D Prototypes

We provide 3D printing services for rapid prototyping. Utilizing customer-supplied computer-aided design (CAD) files, our team can supply polymer models or functional metal components to help customers not only visualize the end product, but also test it prior to full production. This saves on costs you would otherwise invest in tooling or conventional metal fabrication techniques.

Quality Metal Components From USTEK

The quality and performance of your metal component will depend on your metal supplier and fabricator. At USTEK, we’re committed to offering numerous types of metal materials and fabrication services to meet our customers’ needs. Since 1987, our team has offered precise metal components coupled with cost-efficiency and timely deliveries. Contact us today to learn more about our material options and metal sourcing capabilities.